Do you really want to soak the filter paper before brewing after all?

Curious Saya has been plagued by differing opinions on this issue for quite some time. Though some have performed experiments and written articles, she has never done them herself and finally could not restrain herself.

So on a sunny and slightly muggy morning it seemed destined for taking care of things.

Saya got together with Dabai to conduct an experiment pitting traditional methods against uncommon ones.

-Background-

We have heard positive and negative reasons for soaking the filter paper:

These reasons have been heard from the mouths of baristas who use different brewing techniques. We don’t know if these baristas have ever done these experiments, but they absolutely inspired us to do this experiment.

-Experiment-

Experiment filter cups: hario V60 ceramic filter cup, kalita stainless steel cake cup, bonavita ceramic smart cup

Experimental filter paper: Mola, V60 bleached filter paper

Experiment brewer: SCI Brewing Instructor Dabai

Experiment coffee: Torch Mountain Man Coffee Beans

Participating Q-Graders: Internet Persona Joel, Roast Master Little Cabbage, and Curious Saya

Experiment objective: To compare the TDS, extraction rate, taste and texture of coffee brewed from soaked and non-soaked filter papers under the same conditions of filter cup brewing, water temperature and filter paper.

Within this process, TDS will be measured by a measuring instrument, the extraction rate will be calculated by a formula, and the taste will be recorded by three Q-Graders. The table of their notes is below:

Instructor Dabai kept performing the test over and over, and our three Q-Graders kept on drinking.

They became a bit excited from all the drinking(I hope they didn’t drink too much…)

Now, to come back to the subject, the final results were quite interesting.

First and foremost, a table of the combined three Q-Grader evaluations:

We used these three filter cups to make coffee with soaked filter paper and non-soaked filter paper, respectively. When scoring, we looked at seven different details of the coffee, and summarized the following points:

1. Using non-soaked filter paper or soaked filter paper has little effect on the aromatic trend of the coffee, but there is a clear discrepancy in taste;

2. Coffee brewed without soaked filter paper is stiff, dry and tart, and coffee brewed with soaked filter paper is a distinctive and smooth;

3. When looking at the extraction rate, we can see that the extraction rate of soaked filter paper is marginally higher than that of non-soaked filter paper, though the difference is inconsequential.

-Further Discussion: To Soak with Cold or Hot Water -

After we answered the problem of whether to “soak or not soak the filter paper before brewing,” we discovered another problem: if you must first soak the filter paper, is it better to use cold or hot water?

Consequently, the three decided to seize the moment and simply perform this experiment as well.

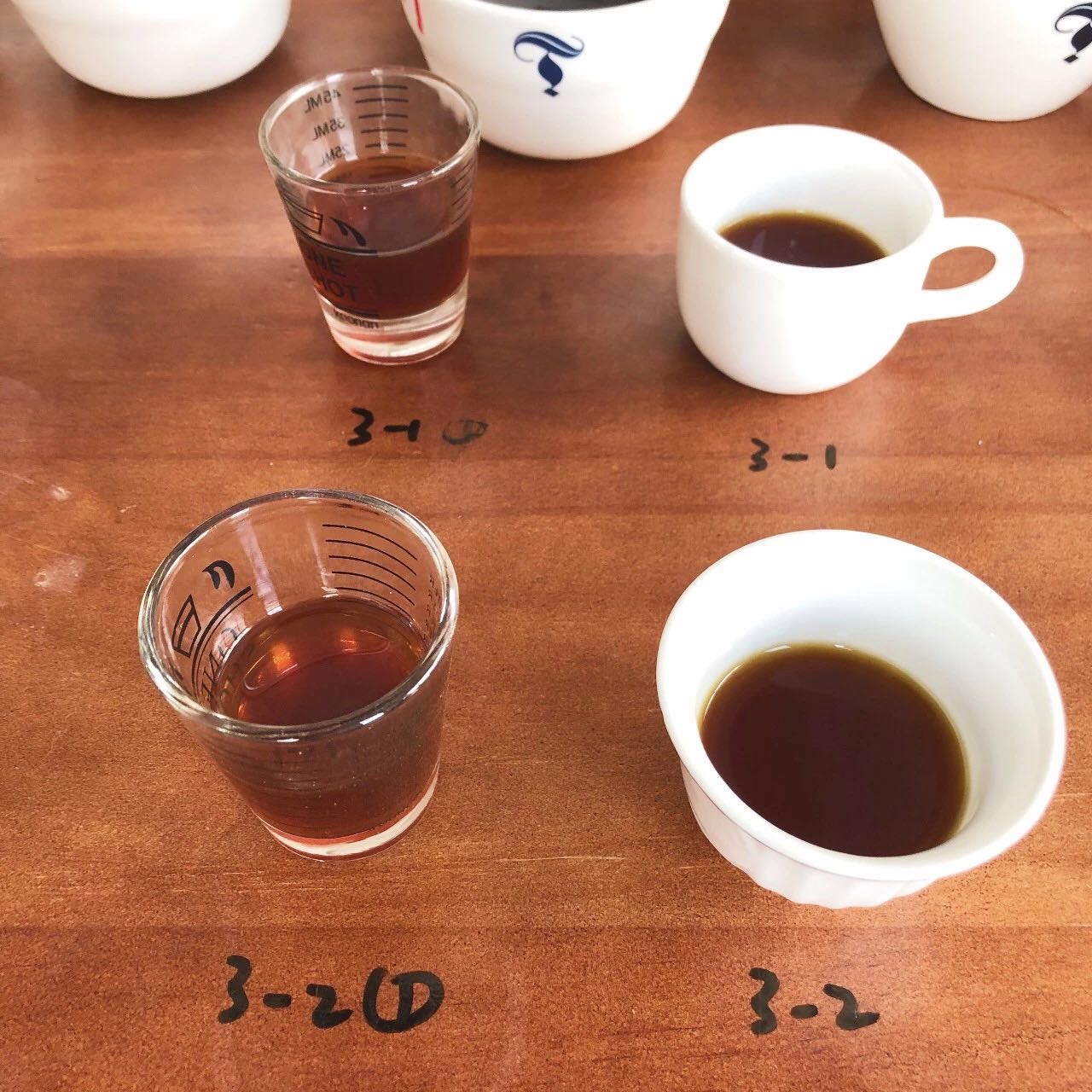

We directly used V60 to do the test, brewing two cups of coffee. Before making each cup, we soaked the filter paper, once with hot water and the other with cold water. The data is as follows:

Conclusion:

The sense of sweetness of the coffee made with filter paper soaked with cold water is slightly better. The texture is thick but mixed, and after it cools, the flavor becomes bitter and astringent.

Of course, we believe that every instrument, every filter paper, and whether or not it is soaked are all ways of making coffee more spectacular. Some friends who like Japanese-style brewing will choose to not soak their paper. The results from this experiment are just a reference.

If you have interested friends, please feel free to conduct your own experiments, and we can communicate about our findings together.