Roasting is an art, but it is not as attractive as the performance art on the street. It is an art that combines chemistry, engineering and a lot of other sciences. It requires the roasters to be devoted to their industry. Only then can they become true artists.

When we think about “art”, most of us will think about the great master pieces, paintings such as the Mona Lisa, structures such as Louvre, or musical works such as “The Flight of the Bumblebee”, but how many of us will think of the master piece that can be found in a cup of coffee?

As with the great masters of any medium, the coffee roast masters that create the flavors for each bean and blend work tirelessly to perfect their craft, and have a clear vision and goal for what their end result should be, and they never accept anything but perfection.

Before any artist can begin a great work, he or she must be intimately familiar with their medium and their tools. Likewise, before you start to roast, you really need to know and understand your roaster and your beans.

Maybe you have mastered some flavor profiling or maybe you are a cupping master, or you already know your roasting machine very well. But if you really want to be a great master roaster, you must be obsessive when it comes to understanding your beans.

Each bean is unique and special, and even beans from the same region and the same farm can vary from year to year. Finding the ideal roasting method for a certain bean depends not only on mastery of the roaster, but also depends directly on how well you understand this bean. Only then can you realize the full potential of your coffee.

1、Getting to Know You(r Beans),

Getting to Know All About You(r Beans)

So before we start to roast, let’s take a moment to discuss our special little beans.

Assessing the Quality of Our Beans

The quality (or grade) of our beans generally depends on several key characteristics, and these help us determine what roasting profile we will choose.

When grading green beans, we must first assess the size and density, moisture content, and other factors. After this, we should consider the different processing methods and understand how these different methods can affect the roasting and ultimately the different flavors in the cup.

Understanding the processing methods of the beans is crucial, but we should also be able to identify the defects in our beans and how these were caused.

Common defects include black, sour, and damaged beans, commonly caused by insects. We should avoid roasting these beans whenever possible, as they will seriously affect the flavor in the cup (what we refer to as “unclean” or “dirty” flavors).

So how do grade our beans? Let’s jump into this topic now!

Step 1: General Background

We need to determine the basic features of our beans: origin, processing method, drying method, coffee tree varietal, total yield and even coffee age.

Step 2: Physical Characteristics

We need to understand the physical characteristics of our coffee beans: odor and appearance, moisture content, density and weight of the green coffee, and whether or not the shape of the coffee bean is completely developed.

Odor

If the smell of our coffee beans is herbal, fruity, floral and even woody it is acceptable.

However, if you notice smells like chemicals, smokey, heavy earthiness, or fermented, then there are most likely some problems with our coffee.

Color

According to the different processing methods and environment (orterroir), the green beans’ color will be different. Normal colors include light green, light blue-green, light gray, and light yellow.

However, we find black, blue, gray, red, or white beans, then these should not used for roasting.

Appearance

The shape of normal coffee beans will be different according to different coffee varieties or processing methods. This is a very deep topic, so we will save this discussion for a later article.

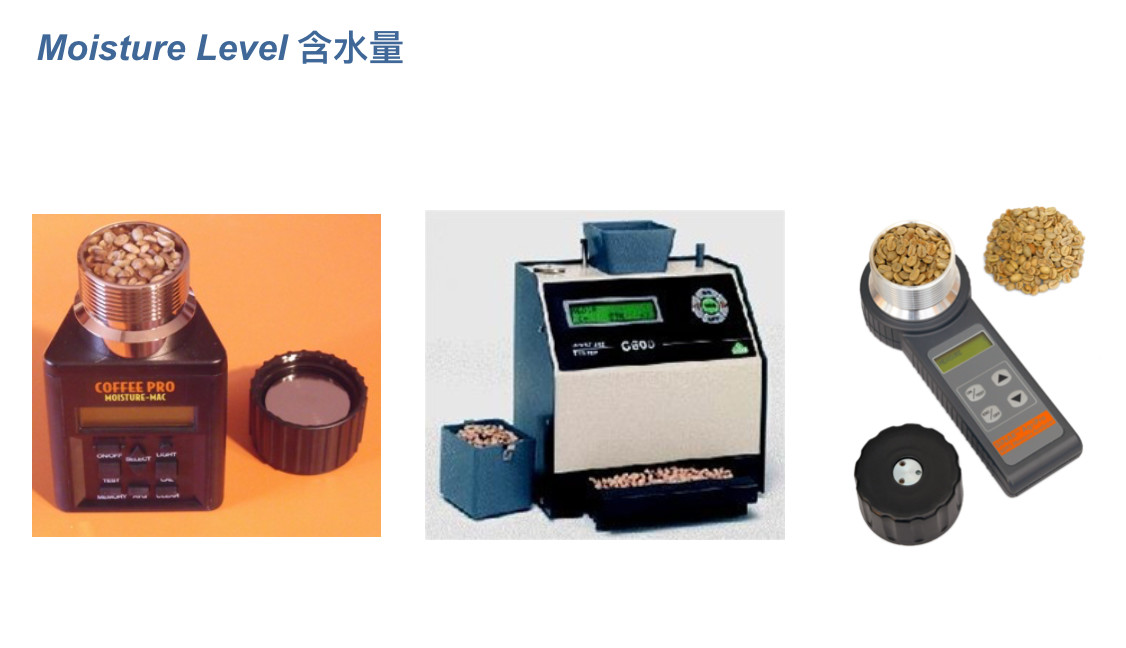

Moisture content

Before roasting, the moisture content of coffee beans should be about 10-12.5%.

Density

For different densities of coffee beans, we also want to use different roasting methods.

Step 3: Defect Grading

Identify defects; classify defects by type; classify coffee beans according to grading standards. You can specifically refer to a previous article we wrote before. Click on the link below to view:

》》SCAA Standard Green Bean Grading

Step 4: Bean Size

The size of coffee beans is usually determined by using different size filter meshes in the drying process. In general, the number of coffee beans sizes vary from “12” to “20” grade.

Normally we use coffee beans above size 15 mesh. If the number of the mesh is less than 13, the number of defects will most likely increase.

When we roast coffee, we need to try not to blend more than 3 meshes at the same time, otherwise we will lose control during roast profiling. This may be because the density of the coffee beans are too different.

Understanding our green beans is only the first step in the process of creating a work of coffee art.

From here, we can master the roasting profile, create a blend of different beans with beautifully paired flavors, extracting these flavors, and mixing with milk (or anything else you can think of!), before finally serving to a customer, a friend, or enjoying ourselves.

I hope this has been helpful for you! The road to becoming a master for any profession or any skill is long and difficult, but always maintain an inquisitive spirit—never stop questioning and never stop experimenting!

The greatest results are produced when we not only have expertise in our field, but when we can also see our work through the eyes of a novice, and never stop trying new things!

Each step in the coffee chain requires a lot of knowledge, but through experimentation, we can create new and beautiful results. Above all else, enjoy your coffee!